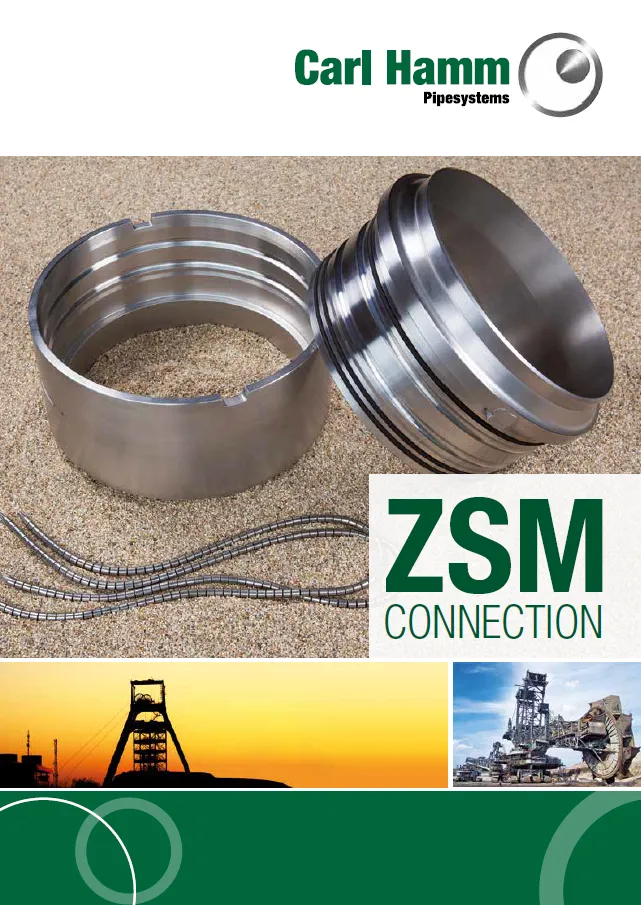

ZSM SYSTEMS

ZSM Systems covers various options and applications. View our products below or download our PDF brochure

ZSM Connection with corrosion-proof coating

• Reduced installation dimensions.

• Quick, easy and safe to assemble/disassemble.

• No special tools.

• The ZSM Connection permits low deflections.

Carl Hamm ZSM Connections

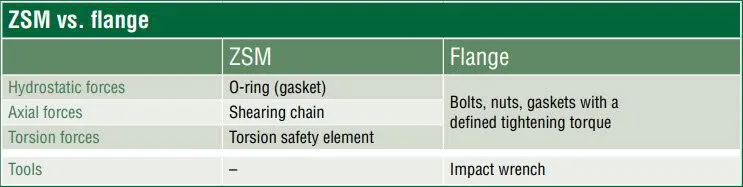

The tight sleeve connection -ZSM - is an axial non-positive and detachable pipe connection. Used as a vertical riser pipe in open pit and underground mines as well as in deep wells.

Our patent-protected tight sleeve system is a unique alternative to other conventional connection systems due to its quick and easy assembly/disassembly and space-saving design. All of this ensures considerable cost savings through the whole life cycle.

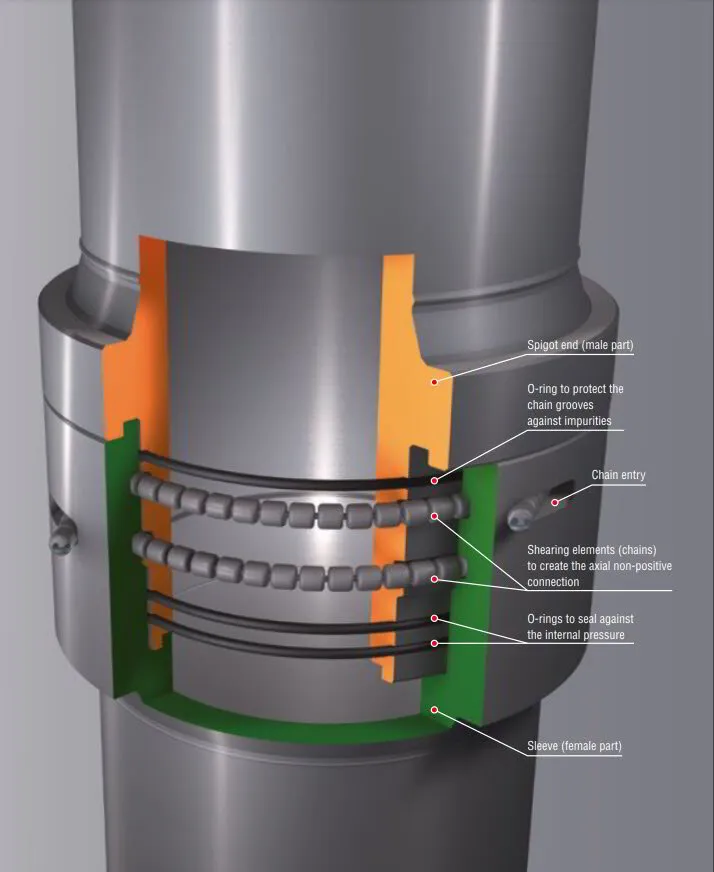

ZSM DETAILED DIAGRAM

The tight sleeve connection -ZSM - is an axial non-positive and detachable pipe connection. Used as a vertical riser pipe in open pit and underground mines as well as in deep wells.

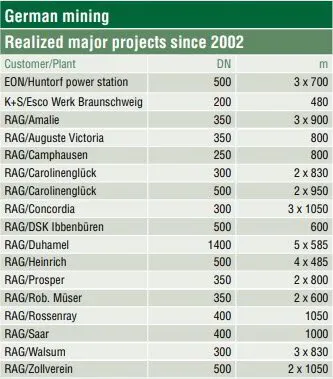

The success story of the Carl Hamm ZSM Connection

The ZSM Connection was launched in 1992 as a simple, quick, tight connection – initially used as a lost casing in well sinking.

The potential of this connection was recognised in the mid-1990s. The ZSM Connection was further developed in cooperation with Rheinbraun (now called RWE Power).

The objective was to create a medium-carrying, axially load-bearing,

quick-to-install system with detachable connections. The results revolutionised the well operations of Rheinbraun. As a consequence, all wells are now operated with ZSM pipelines.

The ZSM Connection was further developed for use underground on the basis of this technical success.

In 2003, the first riser pipe was equipped with ZSM-Technology in German hard coal mining – Heinrich colliery, Essen. In such cases the higher tensile and compressive loads as well as the high safety requirements in a shaft used for descent were taken into account.

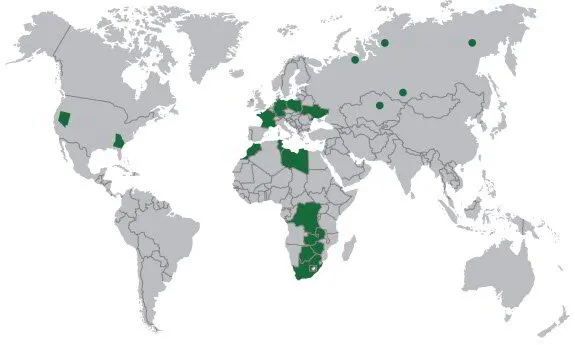

The ZSM Connection was continuously developed and also successfully used in a wide range of installation situations in German mining and more recently internationally as well.

Easy Installation

Step 1

• The spigot end (male part) has three sealing grooves and two chain grooves on the outside.

• The sleeve (female part) has two chain grooves

on the inside.

• O-rings are inserted into the sealing grooves of

the spigot end.

Step 2

• The spigot end and sleeve are pushed together without

any additional aids.

• The seal is created in this way.

• The optional anti-torsion devices absorb the torsional moments of the pump.

Step 3

• The chain grooves form two annular cavities.

• Shearing elements (chains) are inserted manually through openings in the sleeve. Tools are not required.

• The spigot end and sleeve therefore have an axial non-positive connection.

More Information

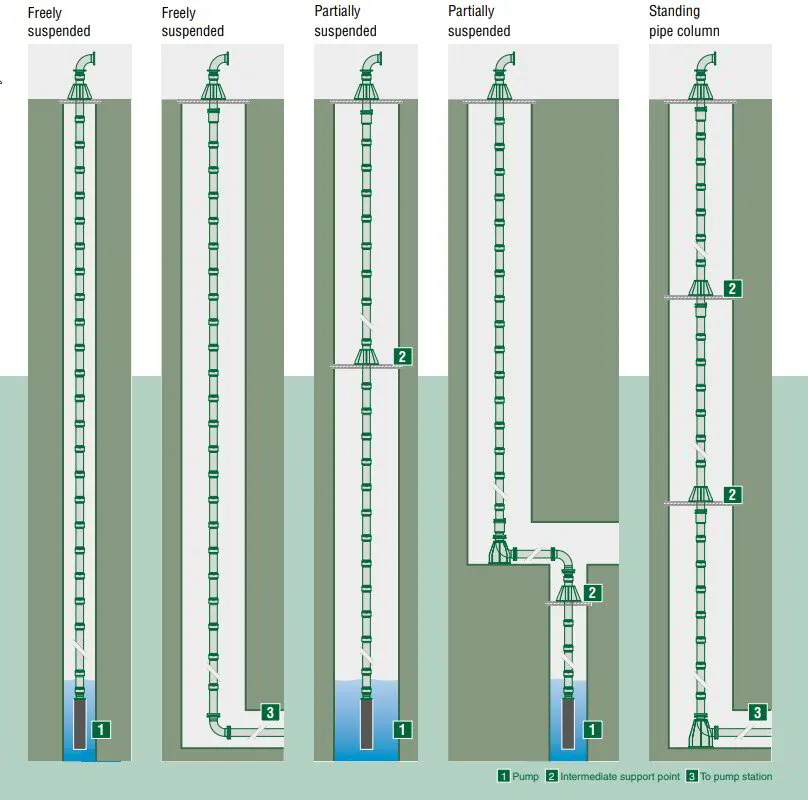

Carl Hamm ZSM in underground mining

The ZSM Connection excels owing to its cost-effectiveness, especially when used with high-performance submersible pumps.

Here it shows off its system advantages of time-saving assembly and disassembly.

In confined installation situations the low installation dimensions of the ZSM Technology allow optimised pipe diameters.

The easy disassembly of the pipes allows to change a pump quickly.

Downtimes due to maintenance and repairs are reduced to a minimum.

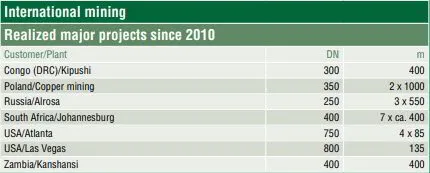

Carl Hamm ZSM In Deep-Well Sinking

The ZSM Technology has been used for more than 20 years in German brown coal open-pit mining to manage the groundwater level. Especially in well galleries with a high amount of interconnected wells the advantages of the ZSM-connection are emphasized.

The frequent pump changes – due to high solids content of the pumped medium and the moving open-pit – can be executed much faster because of the very short assembly and disassembly times. The low installation dimensions of the connection allow higher pipe diameters. As a result, lower velocity can be achieved at the same pump capacity by even enlarging the system efficiency.

Also this ensures a substantial extension of the service life of a pipeline and the pump used.

The ZSM Technology is also very popular for applications in irrigation projects with deep wells, especially due to the advantage of the low installation dimensions and short installation time and its resultant benefits.

Everything From One Source

We supply ready-to-install ZSM Pipelines.

To offer optimum solutions, we apply to our experience from over 90 years in the mining industry. We ensure to support our customers in all phases of their projects.

Budget planning on the basis of your information

Planning of a pipeline including all components required

Static calculations.

Preparation of the overview and detail drawings

Design of the ZSM Components on the basis of the specific requirements.

Destructive tensile testing of the ZSM Components.

Professional production of the complete pipeline using the in-house process – according to the specific manufacturing and test sequence plan.

Depending on the requirement, we produce ZSM Pipelines made of: Carbon Steels, Stainless Steels, Duplex Steels.

Inside and outside coating systems.

Non-destructive tests of the welds.

Worldwide shipment.

Support during assembly.

Quality Management

A certified quality management system was introduced in 1997. The development and design section was added in 2010. As a certified specialised welding company, we satisfy national and international standards.

Certificates, permits (e.g. Germanischer Lloyd) and process inspections as well as the personal qualifications of our employees in the production and quality assurance departments guarantee a constantly high standard of quality.