Expertise In Steel

Our expertise in steel covers various options and applications. View our products below or download our PDF brochure

Ready To Get Started?

Carl Hamm Group

Enjoy the benefits of working with a powerful supplier

dedicated to meeting your specific requirements – with

over 85 years' experience in the industry.

We offer design services, manufacturing and installation

support for your project. Our top-notch applications

engineering and innovative approach provide the basis

for optimum solutions for your problems at hand.

Our key to success: solid partnerships with our customers -

built on trust and powered by our experience and know-how.

Our mission is to provide highest-quality products and

services – with expert engineering for optimum performance in your project.

What We Offer

- Extensive raw material stocks

- Modern equipment for wide range of machining operations

- On-time delivery

- Support in installation

- Shipping to destinations worldwide

- Documentation and traceability

- Quality management

What We Offer

- Reliability

- Fast delivery times

- Highly motivated employees

- Outstanding service

- Flexibility

- Professional approach

- Innovative ideas

OUR HISTORY

Back in April 1929, entrepreneur Carl Hamm founded a pipe manufacturing works at our present site in Kupferdreh, a district of

Essen / Germany. Today the company is under the management of the fourth generation of the Hamm family.

Decades of experience as a supplier to the international mining industry, a sector known for strictest safety requirements, are our best reference as a high-performance pipe system provider. Our pipe systems are used in a wide variety of sectors including mining, power

generation and supply, industrial processes, building services and stationary fire protection systems.

WORK WITH US AND BENEFIT FROM OUR

- Over 85 years' experience in the industry

- Decades of experience in the mining sector

- Readiness to master the challenges of the future

OUR HISTORY

Back in April 1929, entrepreneur Carl Hamm founded a pipe manufacturing works at our present site in Kupferdreh, a district of

Essen / Germany. Today the company is under the management of the fourth generation of the Hamm family.

Decades of experience as a supplier to the international mining industry, a sector known for strictest safety requirements, are our best reference as a high-performance pipe system provider. Our pipe systems are used in a wide variety of sectors including mining, power

generation and supply, industrial processes, building services and stationary fire protection systems.

WORK WITH US AND BENEFIT FROM OUR

- Over 85 years' experience in the industry

- Decades of experience in the mining sector

- Readiness to master the challenges of the future

TODAY

Expertise, experience, innovations, state-of-the-art

fabrication equipment and highly motivated staff provide the basis for success of the products and systems we provide.

Offering the flexibility of a modern medium-sized company and experience from over 85 years in the business, we are ready to master the challenges of the future.

A wide range of certifications and agency approvals ensure compliance with applicable regulations and standards throughout all production processes.

Our decades of experience and strengths are yours to profit from.

We will meet your specific needs and exceed your expectations.

TODAY

Expertise, experience, innovations, state-of-the-art fabrication equipment and highly motivated staff provide the basis for success of the products and systems we provide.

Offering the flexibility of a modern medium-sized company and experience from over 85 years in the business, we are ready to master the challenges of the future.

A wide range of certifications and agency approvals ensure compliance with applicable regulations and standards throughout all production processes.

Our decades of experience and strengths are yours to profit from.

We will meet your specific needs and exceed your expectations.

LOCATIONS

ESSEN

Gasstraße 12 - 45257 Essen

Germany

info@carl-hamm.de

Tel.: +49 (0) 2 01 / 8 48 17 - 0

Fax: +49 (0) 2 01 / 8 48 17 - 70

RAVENSBURG SALES OFFICE

Wilhelm-Hauff-Straße 12

88214 Ravensburg

Germany

Wolfram Widmann

widmann@carl-hamm.de

Tel.: +49 (0) 7 51 / 2 85 09 - 60

Mobile: +49 (0) 1 71 / 2 74 11 55

Fax: +49 (0) 7 51 / 2 85 09 - 61

HAMBURG SALES OFFICE

Alter Kirchweg 7

21217 Seevetal

Germany

HAMBURG SALES OFFICE

Alter Kirchweg 7

21217 Seevetal

Germany

Kai Stelzner-Ripka

ripka@carl-hamm.de

Tel.: +49 (0) 40 / 21 90 81 - 11

Mobile: +49 (0) 1 60 / 5 35 30 02

Fax: +49 (0) 40 / 21 90 81 - 13

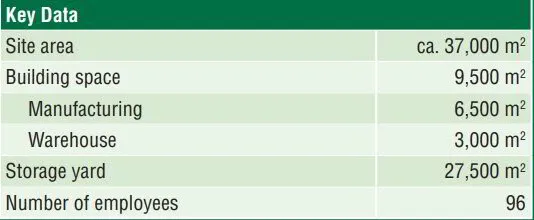

CORPORATE FIGURES

Back in April 1929, entrepreneur Carl Hamm founded a pipe manufacturing works at our present site in Kupferdreh, a district of

Essen / Germany. Today the company is under the management of the fourth generation of the Hamm family.

Decades of experience as a supplier to the international mining industry, a sector known for strictest safety requirements, are our best reference as a high-performance pipe system provider. Our pipe systems are used in a wide variety of sectors including mining, power generation and supply, industrial processes, building services and stationary fire protection systems.

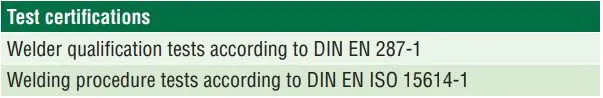

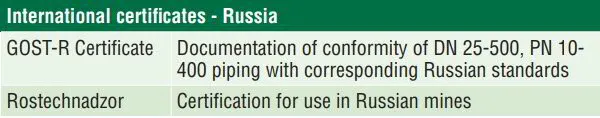

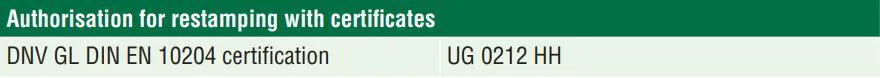

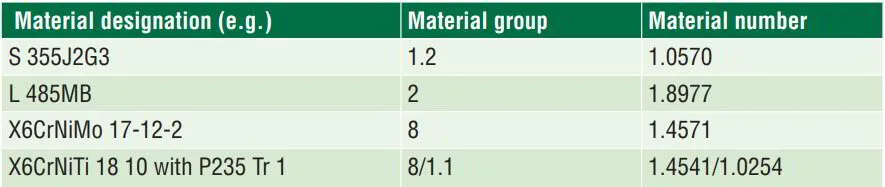

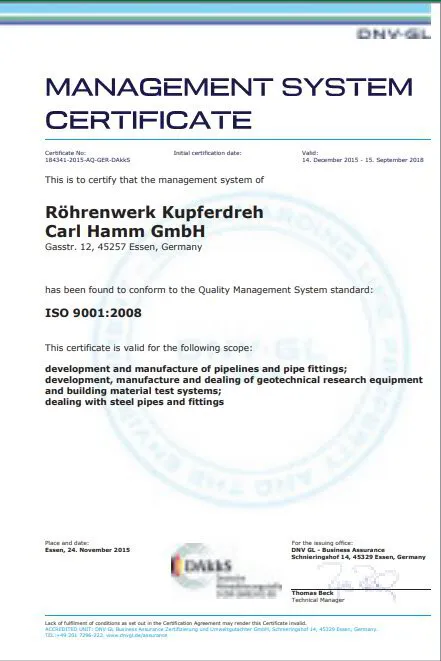

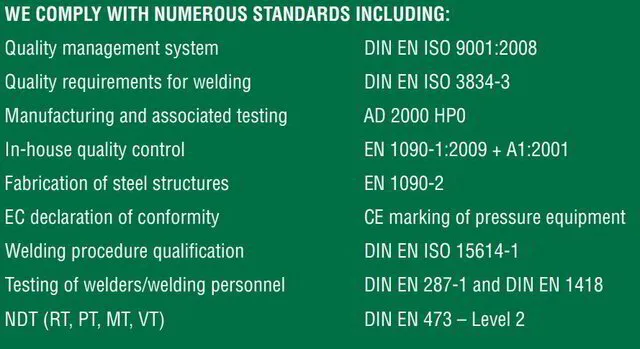

CERTIFICATES & MATERIALS

Our certified quality management system meets strict national and international standards. We can produce a wide variety of procedure qualification certificates and welders' individual

qualification certificates for our MAG, MIG, WIG, SAW and automated welding processes – as well as our certificate for marking transfer (restamping) authorisation for metallic

products with DIN EN 10204:2005 Type 2.2 and 3.1 Test Certificates.

All manufacturing processes are carried out in accordance with our ISO 9001:2008-certified quality management system. Various certifications of our testing procedures and personnel assure highest consistency and of our QC testing.

Other areas of our company also operate in accordance with our ISO 9001:2008-certified QM system:

• Development and design of pipes and fittings

• Manufacturing of pipes and fittings

• Trading of steel pipes and pipe accessories

We also have compliance certificates for

Russian standards.

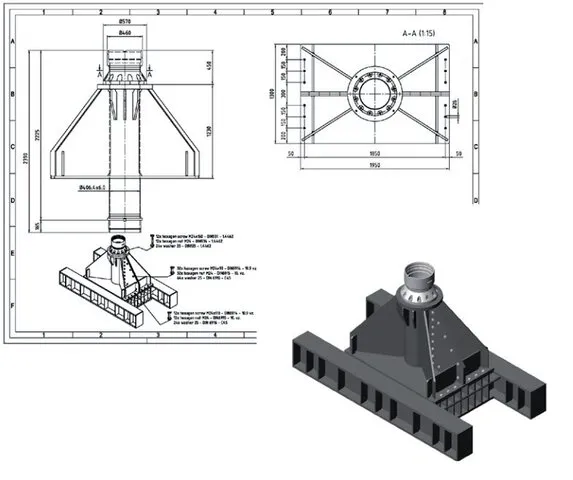

DESIGN AND DOCUMENTATION

DESIGN

You provide the idea, we do all that is needed to make it reality!

Design and development – the link between sales and manufacturing – are among the ISO-9001 certified functions carried out by our company.

In our company these activities also include preparation of:

• Drawings

• Calculations

• Parts lists

• Risk assessments regarding machine safety

• Operating instructions

We carry out design of your products in-house or in conjunction with expert engineering consultants in accordance with the circumstances at hand.

Utilising all required resources and know-how, we realise optimum technical solutions which are custom-designed to your specific project requirements.

DOCUMENTATION

We carry out comprehensive documentation for all manufacturing operations:

• Pipe systems

• Machine systems

• Auxiliary / mounting structures

You receive all important documentation for your products including:

• Material certificates

• Welding seam lists, test methods and reports

• Certificates and certifications

• Shipping documents

Manufacturing and shipping documentation are

provided separately wherever possible for the sake

of clarity and convenience.

The Benefits We maintain and provide documentation beyond the extent required by legal regulations.

This reflects the high quality of the products we supply, keeps pace with ever-stricter operational safety legislation and provides other advantages as well:

• Accelerated inspections by approval agencies and third-party supervisory organisations (TÜV, DNV GL Group, etc.)

• Potential for reduced insurance premiums

DESIGN AND DOCUMENTATION

DESIGN

You provide the idea, we do all that is needed to make it reality!

Design and development – the link between sales and manufacturing – are among the ISO-9001 certified functions carried out by our company.

In our company these activities also include preparation of:

• Drawings

• Calculations

• Parts lists

• Risk assessments regarding machine safety

• Operating instructions

We carry out design of your products in-house or in conjunction with expert engineering consultants in accordance with the circumstances at hand.

Utilising all required resources and know-how, we realise optimum technical solutions which are custom-designed to your specific project requirements.

DOCUMENTATION

We carry out comprehensive documentation for all manufacturing operations:

• Pipe systems

• Machine systems

• Auxiliary / mounting structures

You receive all important documentation for your products including:

• Material certificates

• Welding seam lists, test methods and reports

• Certificates and certifications

• Shipping documents

Manufacturing and shipping documentation are provided separately wherever possible for the sake of clarity and convenience.

The Benefits We maintain and provide documentation beyond the extent required by legal regulations.

This reflects the high quality of the products we supply, keeps pace with ever-stricter operational safety legislation and provides other advantages as well:

• Accelerated inspections by approval agencies and third-party supervisory organisations (TÜV, DNV GL Group, etc.)

• Potential for reduced insurance premiums

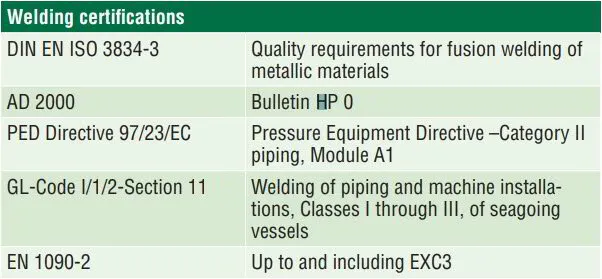

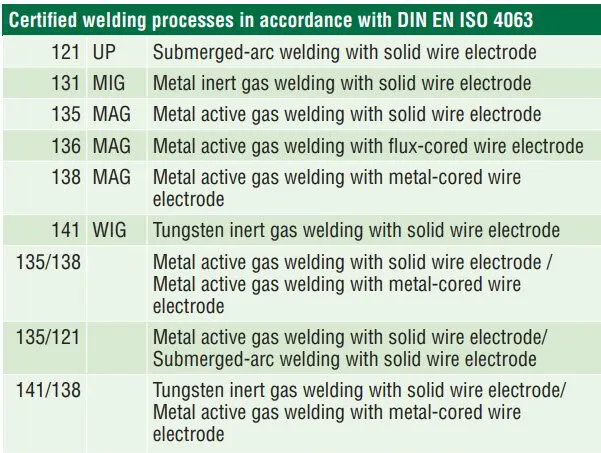

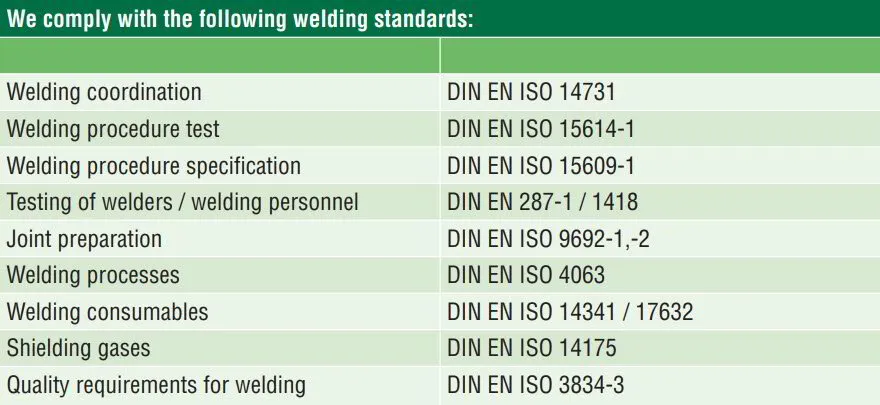

WELDING

We are certified welding specialists for black steel and stainless steel in compliance with a wide variety of national and international standards

and codes. Our compliance is assessed and confirmed by independent supervisory

agencies including DNV GL and TÜV.

Our capability to satisfy your exacting requirements is documented by our certifications to :

• AD2000HP0

• Pressure Equipment Directive 97/23/EC, Category II, Module A

• DIN EN ISO 3834-3

• EN 1090-2

and other codes as well.

All of our welders have - as a matter of course - valid test certification for the welding processes carried out. Our welders regularly take part in continuing education courses which keep them updated on state-of-the-art technologies and procedures.

Our fabrication facility is divided in two separate processing buildings, one for non-stainless and one for stainless steel.

This prevents airborne particle contamination, ensuring 100 % material purity at all times.

REFERENCES

ARCELOR MITTAL BREMEN / GERMANY – STEEL WORKS

DN 1400 connecting pipeline for deslagging station, high-precision works fabricated components designed from on-site measurements.

VENDÉE / FRANCE

Municipal drinking water supply line, restrained-socket jointed fittings and flap housings, approx. 800 custom fittings DN 250 to DN 700 – steel-PE-CM.

PROSPER COKING PLANT IN BOTTROP / GERMANY

Gas filtering station and pipelines, TÜV tested, DN 1200 to DN 3000

GELSENWASSER AG / HAMBURG WATERWORKS / MUNICH CITY WORKS

Pipelines with standard and custom PE/CM fittings DN 100 to DN 1200

TOWER 185 FRANKFURT / MOORBURG POWER PLANT IN HAMBURG / GERMANY

Prefabrication of manifolds and tanks with different diameters for building services – stationary fire protection systems, cooling, air conditioning

RAG/ZOLLVEREIN IN ESSEN / GERMANY

Dewatering of defunct mining facility, ZSM-jointed DN 500 pipe, 2 x 1000 m in length

WITWATERSRAND / SOUTH AFRICA

Acid mine drainage, ZSM-jointed DN 400 pipe, 7 x 400 m in length, material of construction: duplex stainless

ALROSA / RUSSIA

Mining facility, ZSM-jointed DN 250 pipe, 3 x 550 m in length

LAS VEGAS / USA

Water supply line, ZSM-jointed DN 800 pipe, 150 m in length

WELDING

We are certified welding specialists for black steel and stainless steel in compliance with a wide variety of national and international standards and codes. Our compliance is assessed and confirmed by independent supervisory agencies including DNV GL and TÜV.

Our capability to satisfy your exacting requirements is documented by our certifications to :

• AD2000HP0

• Pressure Equipment Directive 97/23/EC, Category II, Module A

• DIN EN ISO 3834-3

• EN 1090-2

and other codes as well.

All of our welders have - as a matter of course - valid test certification for the welding processes carried out. Our welders regularly take part in continuing education courses which keep them updated on state-of-the-art technologies and procedures.

Our fabrication facility is divided in two separate processing buildings, one for non-stainless and one for stainless steel.

This prevents airborne particle contamination, ensuring 100 % material purity at all times.

REFERENCES

ARCELOR MITTAL BREMEN / GERMANY – STEEL WORKS

DN 1400 connecting pipeline for deslagging station, high-precision works fabricated components designed from on-site measurements.

VENDÉE / FRANCE

Municipal drinking water supply line, restrained-socket jointed fittings and flap housings, approx. 800 custom fittings DN 250 to DN 700 – steel-PE-CM.

PROSPER COKING PLANT IN BOTTROP / GERMANY

Gas filtering station and pipelines, TÜV tested, DN 1200 to DN 3000

GELSENWASSER AG / HAMBURG WATERWORKS / MUNICH CITY WORKS

Pipelines with standard and custom PE/CM fittings DN 100 to DN 1200

TOWER 185 FRANKFURT / MOORBURG POWER PLANT IN HAMBURG / GERMANY

Prefabrication of manifolds and tanks with different diameters for building services – stationary fire protection systems, cooling, air conditioning

RAG/ZOLLVEREIN IN ESSEN / GERMANY

Dewatering of defunct mining facility, ZSM-jointed DN 500 pipe, 2 x 1000 m in length

WITWATERSRAND / SOUTH AFRICA

Acid mine drainage, ZSM-jointed DN 400 pipe, 7 x 400 m in length, material of construction: duplex stainless

ALROSA / RUSSIA

Mining facility, ZSM-jointed DN 250 pipe, 3 x 550 m in length

LAS VEGAS / USA

Water supply line, ZSM-jointed DN 800 pipe, 150 m in length

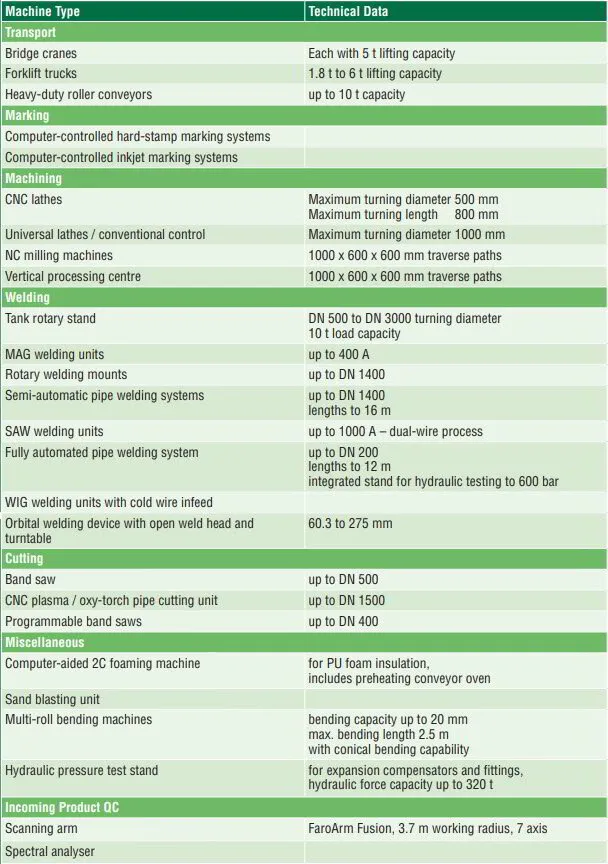

MACHINING CAPABILITES

Thanks to our extensive machinery line-up we can offer you a wide variety of optional features and processing steps:

READY-TO-INSTALL PIPES

• Cut to desired length

• Threaded in accordance with DIN2999/ISO7-1

• Rolled grooves for coupling systems

• Drilled holes

• Threaded fittings, sealed and screwed together

• Pre-installed clamp saddles

• Custom welded components with subsequent

machining steps

• Tailor-made parts (steel or plastic) fabricated in

our in-house turning facility

TECHNICAL CAPABILITIES

• Saw cutting of diameters up to DN 500

• Thermal cutting of diameters up to DN 1500

• Rolled grooves for pipe coupling systems:

DN 25 - DN 800 (AGS available for DN 350 and up)

in lengths from 150 mm to 12,000 mm

• Welding chamfers DIN 2559 Shape 21 and 22

• Mitre cuts from 0 to 45°, up to DN 1400

• DIN 2999 threading from ½" to 6",

in common commercial lengths or custom lengths

• Bending of steel pipes

MACHINING CAPABILITES

Thanks to our extensive machinery line-up we can offer you a wide variety of optional features and processing steps:

READY-TO-INSTALL PIPES

• Cut to desired length

• Threaded in accordance with DIN2999/ISO7-1

• Rolled grooves for coupling systems

• Drilled holes

• Threaded fittings, sealed and screwed together

• Pre-installed clamp saddles

• Custom welded components with subsequent

machining steps

• Tailor-made parts (steel or plastic) fabricated in

our in-house turning facility

TECHNICAL CAPABILITIES

• Saw cutting of diameters up to DN 500

• Thermal cutting of diameters up to DN 1500

• Rolled grooves for pipe coupling systems:

DN 25 - DN 800 (AGS available for DN 350 and up)

in lengths from 150 mm to 12,000 mm

• Welding chamfers DIN 2559 Shape 21 and 22

• Mitre cuts from 0 to 45°, up to DN 1400

• DIN 2999 threading from ½" to 6",

in common commercial lengths or custom lengths

• Bending of steel pipes

COATINGS & CORROSION PROTECTION

SAND BLASTING

• According to DIN EN ISO 12944

• To SA 2.5 purity standard

PE SHEATHING

• Single or double layer systems in accordance with DIN 30670

• With or without fibre-cement coating

CM LINING

• In accordance with EN 10298/DIN 2614

PRIMER COATS / TOP COATS

1 or 2-component primer and top coats based on epoxy resins, available in various RAL colours:

• Zinc phosphate

• Zinc dust

• Micaceous iron oxide, PUR etc.

HIGH-BUILD COATINGS (E.G. FOR REFRIGERATION SYSTEMS)

• In accordance with AGI-Q151-1.3 (2003) / LEED compliant

GALVANISATION IN ACCORDANCE WITH EN 1461

POWDER COATINGS

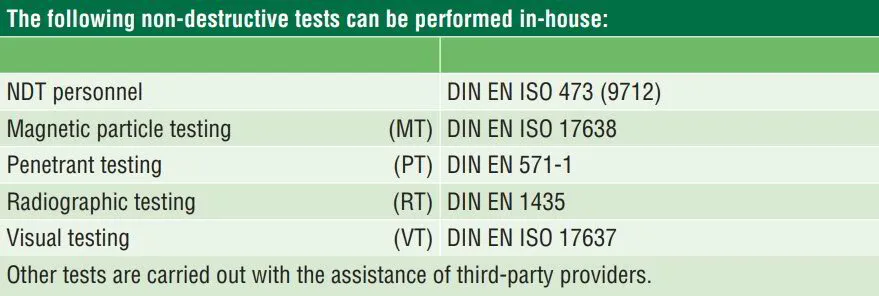

QUALITY CONTROL

Our quality control is carried out in-house by certified test technicians in our QC department. A variety of tests are used to monitor product quality on a continuous basis.

• Nondestructive testing in our in-house x-ray bunker (approx. 2.20 x 14 m in size)

• Cold-water pressurisation tests

• Visual and dimensional inspection

• Real-time radiographic testing (RT), penetrant testing (PT)

and magnetic particle testing (MT)

• Dimensional measurements by 3D scanning arm

• Composition testing

QUALITY MANAGEMENT

We work in certified accordance with a QM system which has been in place since 1997. The system was expanded to include our development and design activities in the year 2010.

We are certified as qualified welding provider.

This certification is verified by periodic inspections confirming compliance with stringent national and international standards.

Our certificates, third-party certifications (from DNV GL and others), welding procedure qualifications and our highly qualified production and QA personnel are your assurance of

consistently high quality.