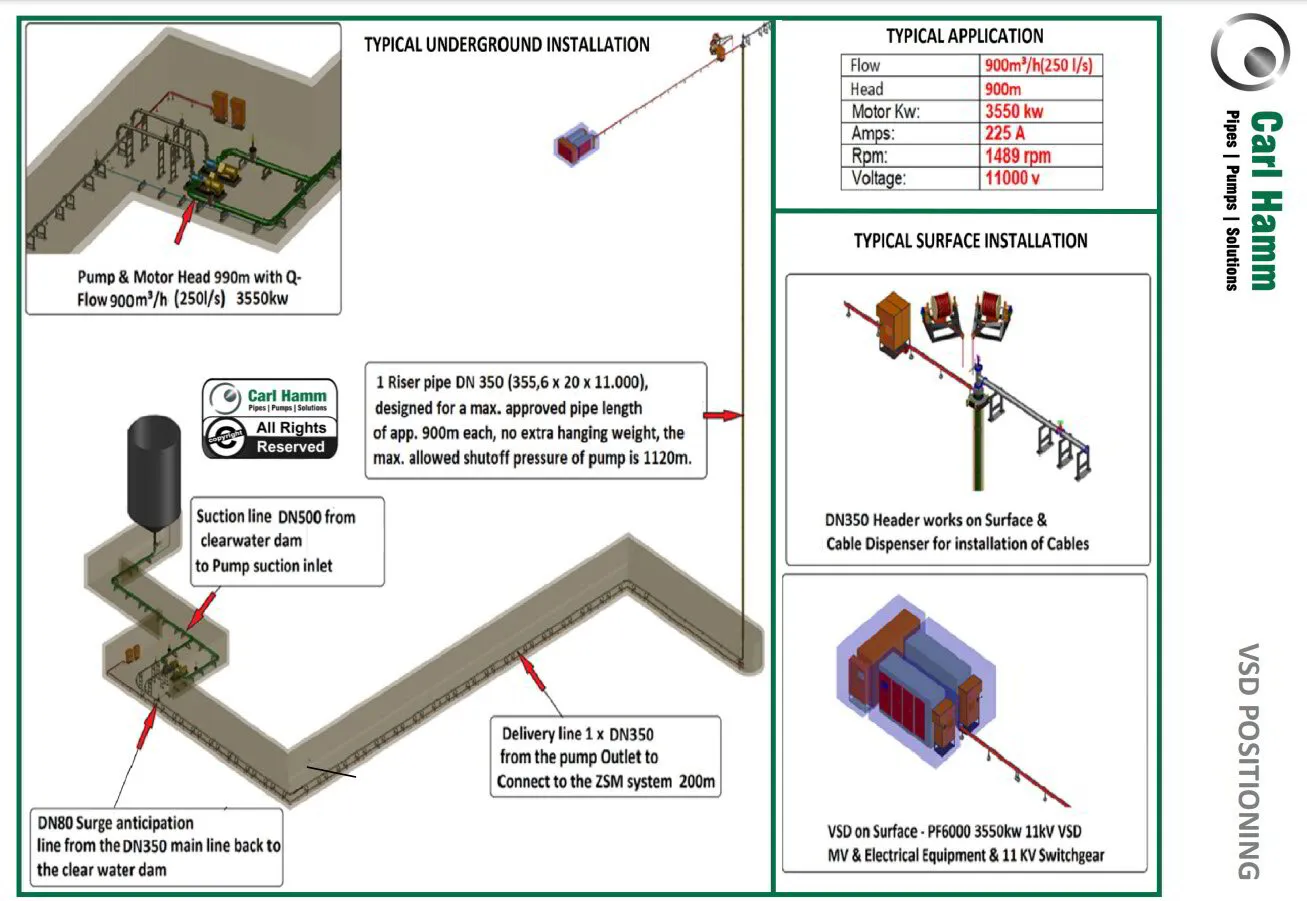

VSD POSITIONING

VSD positioning covers various options and applications. View our products below or download our PDF brochure

VSD Positioning

VSD On Surface

When designing a pump dewatering system it is imperative that all the relative participants have an open and frank discussion. Easily said but not easily achieved.

The “Mine” regardless of process or mineral is primarily established to mine and bring product to market.

A Mine is a large investment to those who participate.

This is irrespective if they are the End user’s, beneficiaries or investment capitalists.

If we consider designing a pump system and the individual departments are asked for input:

Electrical - Will not see any detrimental effect to having VSD units installed underground.

Mining and Civil - Will see no problem creating a chamber to house the Equipment.

Ventilation - Will have no problem with the entire scenario as they are primarily cooling the mine.

Mechanical and Rigging - Will see no problem conveying equipment into position regardless of level.

Production - Will be pleased to have the water out the way to achieve meters.

Each department will do the design based on their personal preferences and all will be satisfied that the best solution has been put in place.

If this scenario then undergoes a complete risk assessment and financial and practical evaluation

comparing Pro’s and Con’s.

A mine makes money when the ore is mined and taken to surface with minimal interference and delays and is delivered to market.

Electricity needs to be supplied from point A to point B to power the pumps, fans etc.

The consideration now is how can this be done without impacting on others and what it could possibly impact.

- MV or HV will have to be taken into the mine.

- This voltage must be transformed underground or MV or HV infrastructure must be installed as required.

- This infrastructure will require a mined chamber, every m² mined for the chamber must go to the surface and will at some time hinder production ore movement.

- The Equipment / Transformer and VSD will generate heat which will require additionalventilation and cooling.

- The Equipment must be kept in humid free / pressurized environment.

- The added risk of flooding.

- An increased effort to service and maintain equipment will be required.

It is almost the same as desludging underground and bringing solid waste to surface instead of pumping the mud. The dry waste will eventually hinder the ore conveyance.

Regardless How This Evaluated

The installation of the transformers and VSD equipment on surface will reduce costs, be easier to maintain and have no added risk of flooding. Designing the mine is a joint effort of all parties coordinated by all departments to achieve a common goal.

The bottom line is with all arguments the route of the power and instrumentation remains between point A and point B. It is all about finding the long term solution, involving all departments that benefits all who are involved on the mine.

To design fine system mechanically that is expensive civilly and that is incompatible electrically is of no benefit. Asking the Ventilation Engineer the impact on heat on running bulk water movement pumps underground versus large submersibles in water with electrical infrastructure on surface. The ventilation cost saving could pay back the redesign in a shorter period than you could ever consider.

Ever compared one lift pumping versus cascade pumping. The saving on reduced equipment will pay back the system in months.

Click On Image To Expand

The installation of the transformers and VSD equipment on surface will reduce costs, be easier to maintain and have no added risk of flooding. Designing the mine is a joint effort of all parties coordinated by all departments to achieve a common goal.

The bottom line is with all arguments the route of the power and instrumentation remains between point A and point B. It is all about finding the long term solution, involving all departments that benefits all who are involved on the mine.

To design fine system mechanically that is expensive civilly and that is incompatible electrically is of no benefit. Asking the Ventilation Engineer the impact on heat on running bulk water movement pumps underground versus large submersibles in water with electrical infrastructure on surface. The ventilation cost saving could pay back the redesign in a shorter period than you could ever consider.

Ever compared one lift pumping versus cascade pumping. The saving on reduced equipment will pay back the system in months.

Click On Image To Expand