HCL CLAMPS

HCL Clamps covers various options and applications. View our products below or download our PDF brochure

The New SMART® Band

Key Features

• 60% reduction in buckle size over 32mm Hybrid

• Improved minimum diameter of 200mm over 32mm Hybrid

• Increase in system strength of 345kgf over the 32mm Hybrid

The new Smart" Band Compact 32mm Banding System is an exciting step forward in the evolution of the Smart" Band range. It combines the best features of both the Smart" Tie and the Smart" Band Hybrid systems to create a superior product.

The Smart® Band Compact reduces the size of the Hybrid buckle by over 60% allowing it to be installed on applications as low as 200mm in diameter. Yet unlike the Smart" Tie it contains glass fibre reinforced yarn allowing it to maintain the superior strength, retention and relaxation features of the Hybrid system.

Furthermore, the innovative technology of over-moulding the buckle directly onto the band has actually produced an increase in the strength and retention of the Compact system. As such the Compact system is now perfectly placed to provide a High Strength, High Retention, Long Life and "quick to fit" strapping method for all major subsea applications including VIV Strake attachment on risers down to 200mm.

The New SMART® Band

Key Features

• 60% reduction in buckle size over 32mm Hybrid

• Improved minimum diameter of 200mm over 32mm Hybrid

• Increase in system strength of 345kgf over the 32mm Hybrid

The new Smart" Band Compact 32mm Banding System is an exciting step forward in the evolution of the Smart" Band range. It combines the best features of both the Smart" Tie and the Smart" Band Hybrid systems to create a superior product.

The Smart® Band Compact reduces the size of the Hybrid buckle by over 60% allowing it to be installed on applications as low as 200mm in diameter. Yet unlike the Smart" Tie it contains glass fibre reinforced yarn allowing it to maintain the superior strength, retention and relaxation features of the Hybrid system.

Furthermore, the innovative technology of over-moulding the buckle directly onto the band has actually produced an increase in the strength and retention of the Compact system. As such the Compact system is now perfectly placed to provide a High Strength, High Retention, Long Life and "quick to fit" strapping method for all major subsea applications including VIV Strake attachment on risers down to 200mm.

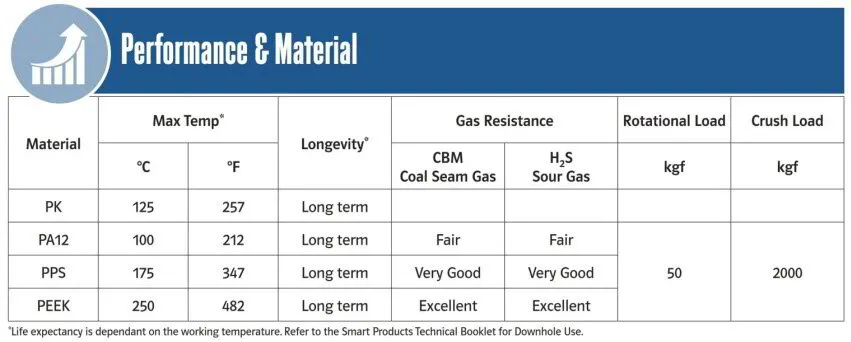

Click Image Below To Enlarge Table

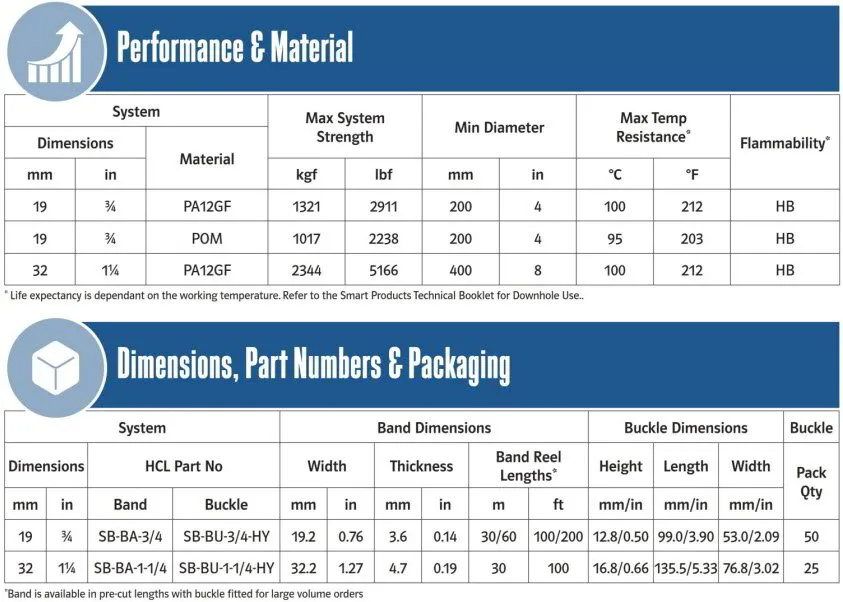

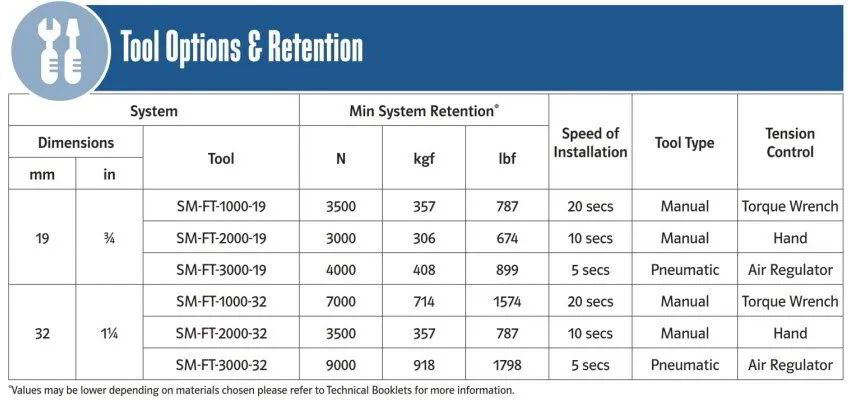

The SMART® Band Hybrid

Key Features

• Low Profile Buckle

• High strength up to 2344kgf (5166lbf)

• Long-life materials

• Safe and easy to fit

• High speed installation

• High retention force – above 918kgf (1798lbf)

• Suitable for divers

The Hybrid name points to the unique patented design of the teeth that sit within the buckle. The low-profile buckle is made from a composite of materials allowing for greater flexibility and providing a significant increase in strength over the Standard system.

Smart® Band Hybrid is HCL’s high strength composite polymer-based band and buckle system. With a range of installation tools including the high speed 3000 pneumatic tool the Smart® Band Hybrid is the ideal solution for

many offshore and onshore applications.

Smart® Band Hybrid is typically used as an alternative to high grade corrosion resistant alloy strapping solutions such as Inconel 625, Monel & Titanium. The Hybrid system combines a number of excellent qualities such as high strength, ease of use, high retention, relaxation properties and long life, to provide the ideal strapping solution for offshore & subsea use.

The SMART® Band Hybrid

Key Features

• Low Profile Buckle

• High strength up to 2344kgf (5166lbf)

• Long-life materials

• Safe and easy to fit

• High speed installation

• High retention force – above 918kgf (1798lbf)

• Suitable for divers

The Hybrid name points to the unique patented design of the teeth that sit within the buckle. The low-profile buckle is made from a composite of materials allowing for greater flexibility and providing a significant increase in strength over the Standard system.

Smart® Band Hybrid is HCL’s high strength composite polymer-based band and buckle system. With a range of installation tools including the high speed 3000 pneumatic tool the Smart® Band Hybrid is the ideal solution for many offshore and onshore applications.

Smart® Band Hybrid is typically used as an alternative to high grade corrosion resistant alloy strapping solutions such as Inconel 625, Monel & Titanium. The Hybrid system combines a number of excellent qualities such as high strength, ease of use, high retention, relaxation properties and long life, to provide the ideal strapping solution for offshore & subsea use.

Click Image Below To Enlarge Table

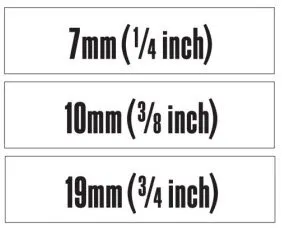

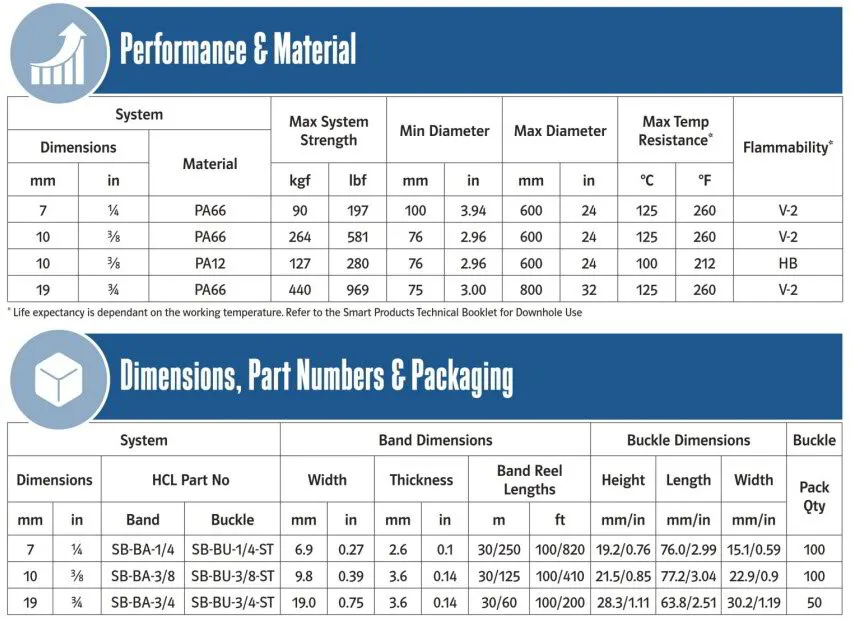

Smart Band Standard

Key Features

• Strength up to 264kgf (581lbf)

• Non-corrosive

• Safe and easy to fit

• Long life materials

• Lightweight easy to use hand tools

• Highly suited for temporary sign installation

The standard name denotes the simplicity of the buckle design, allowing for ease of use & application and presenting itself within HCL's product range as the general industry solution.

Smart® Band Standard is a non-metallic band and buckle system. Highly suited to lightweight applications such as temporary and permanent sign fixing and HVAC.

Smart® Band Standard system is available in a variety of materials, sizes and reel lengths. It offers long-life and non-corrosive properties, making it the ideal alternative to many high grade stainless steel strapping solutions.

Smart Band Standard

Key Features

• Strength up to 264kgf (581lbf)

• Non-corrosive

• Safe and easy to fit

• Long life materials

• Lightweight easy to use hand tools

• Highly suited for temporary sign installation

The standard name denotes the simplicity of the buckle design, allowing for ease of use & application and presenting itself within HCL's product range as the general industry solution.

Smart® Band Standard is a non-metallic band and buckle system. Highly suited to lightweight applications such as temporary and permanent sign fixing and HVAC.

Smart® Band Standard system is available in a variety of materials, sizes and reel lengths. It offers long-life and non-corrosive properties, making it the ideal alternative to many high grade stainless steel strapping solutions.

Click Image Below To Enlarge Table

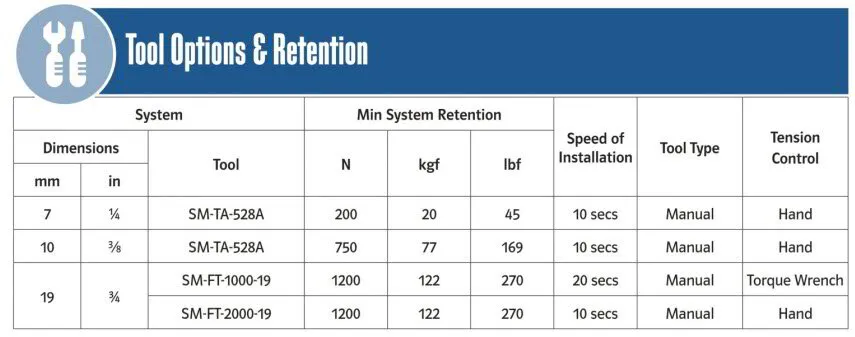

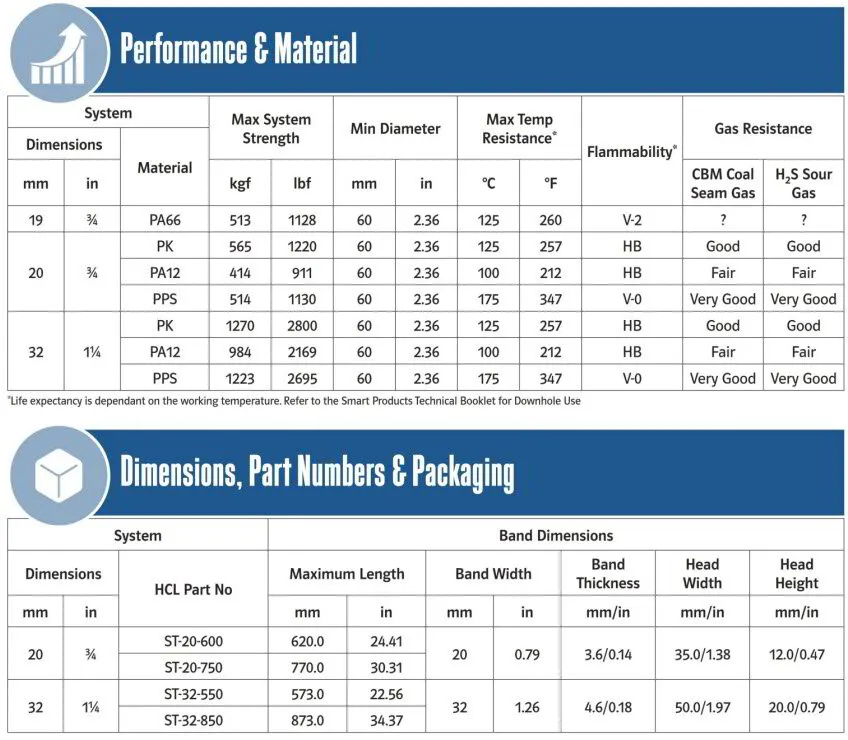

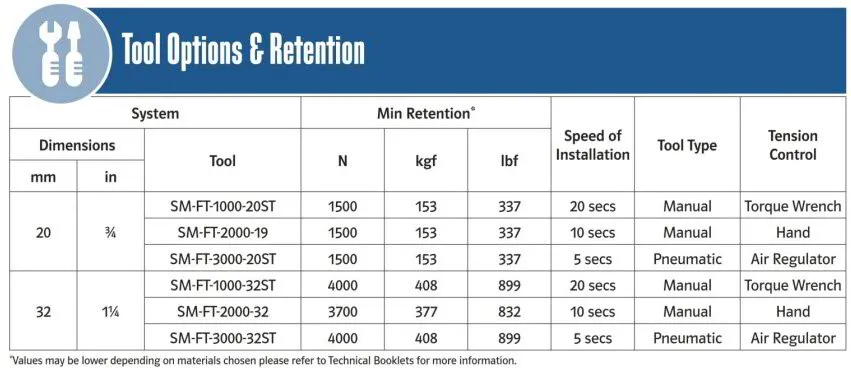

Smart Tie

Key Features

• High temperature resistance up to 175°C (347°F)

• High strength up to 1223kgf (2695|bf)

• Safe and very easy to fit

• High speed installation

• 100% recyclable

• Non-corrosive

• Long life materials

• Suitable for divers

Smart' Tie incorporates the High Strength Tooth Feature 19mm (¾ inch) of the Smart" Band Hybrid and Compact and creates the strongest Polymer Cable Tie in

the World.

Smart® Tie is a patented heavy duty polymer tie wrap, able to withstand system loads in excess of 1200 kgf. It has the advantage of being manufactured from a range of high temperature polymers, giving it superior chemical and temperature resistance up to 175°C.

Lightweight and very easy to use the Smart® Tie has become the ideal downhole cable tie solution and compatibility with the Smart® Protector provides a complete solution for many down-hole applications.

The Smart® Tie is also used widely in offshore applications such as Cable Protection and can be manufactured from long-life PA12.

*Depending on material choice

Smart Tie

Key Features

• High temperature resistance up to 175°C (347°F)

• High strength up to 1223kgf (2695|bf)

• Safe and very easy to fit

• High speed installation

• 100% recyclable

• Non-corrosive

• Long life materials

• Suitable for divers

Smart' Tie incorporates the High Strength Tooth Feature 19mm (¾ inch) of the Smart" Band Hybrid and Compact and creates the strongest Polymer Cable Tie in the World.

Smart® Tie is a patented heavy duty polymer tie wrap, able to withstand system loads in excess of 1200 kgf. It has the advantage of being manufactured from a range of high temperature polymers, giving it superior chemical and temperature resistance up to 175°C.

Lightweight and very easy to use the Smart® Tie has become the ideal downhole cable tie solution and compatibility with the Smart® Protector provides a complete solution for many down-hole applications.

The Smart® Tie is also used widely in offshore applications such as Cable Protection and can be manufactured from long-life PA12.

*Depending on material choice

Click Image Below To Enlarge Table

Smart Courbhastrap

The Problem

Ultra deep water projects are now using new coated pipe with 5 LSPP (five layer Syntatic Polypropylene) & C25 Silicon System. Deep water pressure causes the shrinkage of the coatings generating an OD reduction of up to 10%. The result is a loss in the tension of any bands attached.

The Solution

In collaboration with Group Courbis of France HCL have developed the Courbhastrap. Designed to maintain tension over long life in applications where the diameter increasesor decreases by up to 10% - Qualified by Technip - Total & Hereema for the Kaombo project.

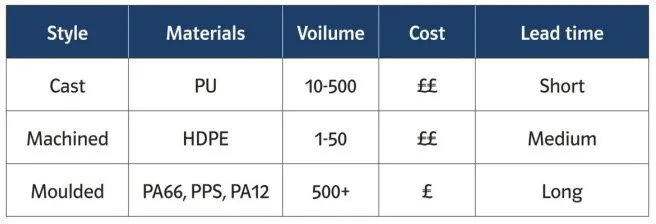

Smart Saddles

HCL have a dedicated team of highly qualified engineers on hand to work with the clients on special projects. HCL can design and supply PU Casted, PP injection moulded or machined parts which work in coniunction with the Smart® Range

specifically the Smart® Band & Smart® Ties. HCL also has an in house Tool Shop to enable a quick response to client inquiries and delivery of a complete package including ties & saddles. These saddles are often referred to as Piggyback saddles and generally used in the attachment of Cables to offshore or Subsea Structures such as Risers, Pipes or Oil Rigs.

Smart Courbhastrap

The Problem

Ultra deep water projects are now using new coated pipe with 5 LSPP (five layer Syntatic Polypropylene) & C25 Silicon System. Deep water pressure causes the shrinkage of the coatings generating an OD reduction of up to 10%. The result is a loss in the tension of any bands attached.

The Solution

In collaboration with Group Courbis of France HCL have developed the Courbhastrap. Designed to maintain tension over long life in applications where the diameter increasesor decreases by up to 10% - Qualified by Technip - Total & Hereema for the Kaombo project.

Smart Saddles

HCL have a dedicated team of highly qualified engineers on hand to work with the clients on special projects. HCL can design and supply PU Casted, PP injection moulded or machined parts which work in coniunction with the Smart® Range

specifically the Smart® Band & Smart® Ties. HCL also has an in house Tool Shop to enable a quick response to client inquiries and delivery of a complete package including ties & saddles. These saddles are often referred to as Piggyback saddles and generally used in the attachment of Cables to offshore or Subsea Structures such as Risers, Pipes or Oil Rigs.

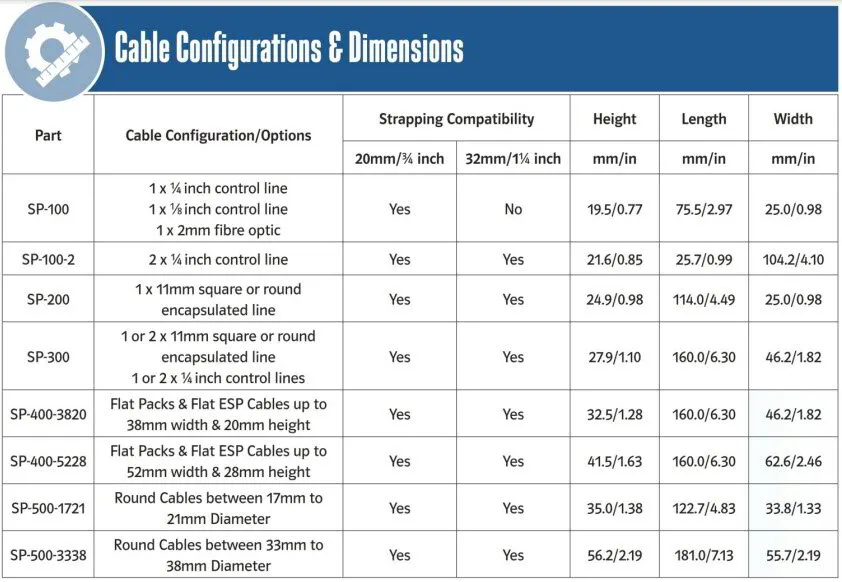

Smart Protector

Key features

• High temperature resistance up to 250°C (482°F)

• Fits any tubing diameter or coupling length

• Can be used for multi-line installations

• Prevents cable snagging

• Low profile and low friction coefficient

• Available for many different cable configurations

• Will not hang in BOP stack

• Easy to mill

A range of polymer cable protectors for use in Downhole, subsea and flow line applications.

The Smart® Protector is a patented product developed in co-operation with Shell. It is designed to operate within restricted annular clearances, to accommodate various tubing diameters, all coupling types and most cable combinations.

The Smart® Protector is not only used as a cable protector downhole it can be used to protect & attach cables in many other situations in conjunction with either the Smart® Band or Smart® Tie. One of the most successful applications is the attachment of Cathodic protection cables to Marine structures.

Smart Protector

Key features

• High temperature resistance up to 250°C (482°F)

• Fits any tubing diameter or coupling length

• Can be used for multi-line installations

• Prevents cable snagging

• Low profile and low friction coefficient

• Available for many different cable configurations

• Will not hang in BOP stack

• Easy to mill

A range of polymer cable protectors for use in Downhole, subsea and flow line applications.

The Smart® Protector is a patented product developed in co-operation with Shell. It is designed to operate within restricted annular clearances, to accommodate various tubing diameters, all coupling types and most cable combinations.

The Smart® Protector is not only used as a cable protector downhole it can be used to protect & attach cables in many other situations in conjunction with either the Smart® Band or Smart® Tie. One of the most successful applications is the attachment of Cathodic protection cables to Marine structures.

Click Image Below To Enlarge Table

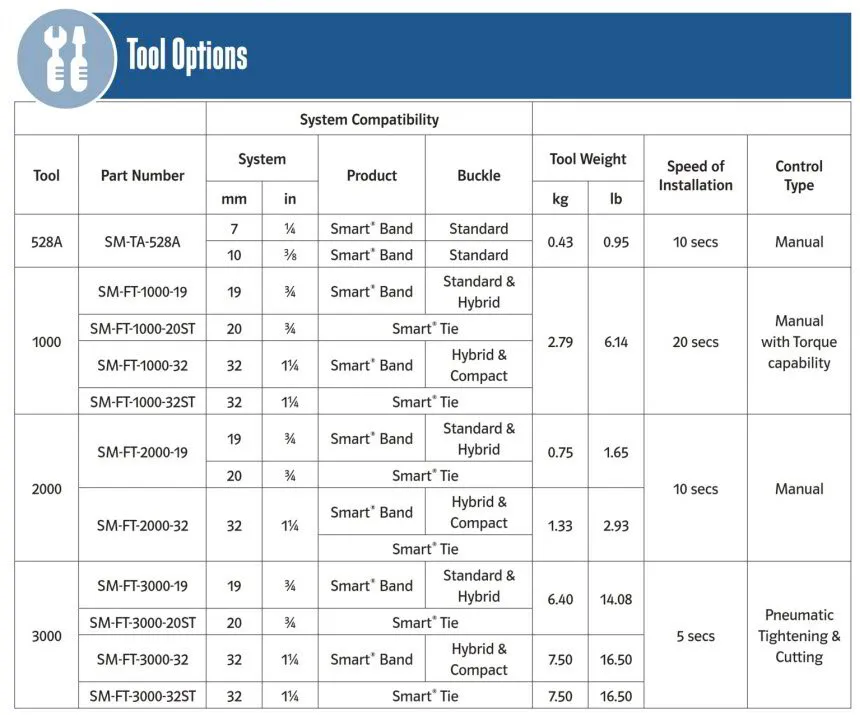

Smart Installation Tools

To enable the installation of the Smart" Band and Smart. Tie HCL had to design and manufacture a range of specific installation tools.

HCL has developed a range of tooling

suitable for the installation of its

range of Smart® Band and Smart® Ties.

a. SM-TA-528A - Lightweight and easy to use, the 528A tool is a manual tool for the smaller Standard systems

b. SM-FT-1000 - A highly specified manual tool which can incorporate the addition of a torque wrench to enable consistent tightening to a set tension

c. SM-FT-2000 - The divers choice. Loved for its exceptional ease of use and its ability to provide high retention forces

d. SM-FT-3000 - Exceptionally fast, the 3000 tool has been designed to enable installation of Smart® Bands and Smart® Ties in under 5 seconds

Smart Installation Tools

To enable the installation of the Smart" Band and Smart. Tie HCL had to design and manufacture a range of specific installation tools.

HCL has developed a range of tooling

suitable for the installation of its

range of Smart® Band and Smart® Ties.

a. SM-TA-528A - Lightweight and easy to use, the 528A tool is a manual tool for the smaller Standard systems

b. SM-FT-1000 - A highly specified manual tool which can incorporate the addition of a torque wrench to enable consistent tightening to a set tension

c. SM-FT-2000 - The divers choice. Loved for its exceptional ease of use and its ability to provide high retention forces

d. SM-FT-3000 - Exceptionally fast, the 3000 tool has been designed to enable installation of Smart® Bands and Smart® Ties in under 5 seconds

Click Image Below To Enlarge Table

SMART PRODUCT

APPLICATIONS

Piggyback Pipelay

There are numerous requirements for piggyback pipe lay including the attachment of Fibre Optic, Methanol and DEH lines (Direct Electrical Heating).

Smart' Band is an ideal solution for attachment in conjunction with piggyback clamps of the piggyback line to the main pipeline.

Cable, Riser & Flowline Protection

The installation of Subsea Cables is widespread. A key issue in this area is cable protection. HCL works alongside Half Shell Cable protection providers to provide a complete solution to the client. The Smart' Band is ideal for such applications offering good impact and abrasion resistance alongside its usual features of high

strength, long life and price competitiveness.

Flotation and Buoyancy

Smart' Band is being increasingly utilised on risers and flowlines for clamping buoyancy and flotation products. Offering High Strength and excellent Elastic and Hydrostatic Compression characteristics the Smart' Band works with the buoyancy products to provide excellent long term retention.

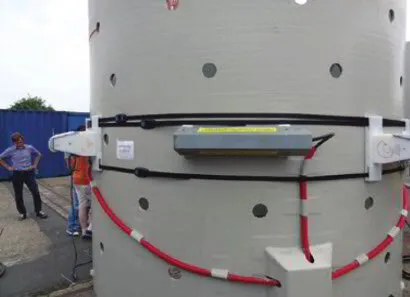

VIV Strakes

Smart" Band is an ideal clamping solution for Strakes to risers and in particular in the deepwater environment. In these areas the Elasticity of the band and the excellent Hydrostatic Compression data become increasingly important. Specifically any applications where there is a susceptibility to compression.

Wind Farms

Attaching cables or brackets to the main structure of a Wind Farm can be expensive and fraught with difficulty. The ease of installation and the non-corrosive nature of the Smart* Band makes it an ideal solution for this application and it has been installed successfully in many projects worldwide.

Cable Attachment

One of the most common applications for Smart* Band offshore is subsea/offshore attachment of all sorts of cables and umbilicals. In many cases Smart' Band is the ideal solution. It's safe and easy to fit and because it has no sharp edges to damage the cables etc. We have an extensive track record in this area.

Sensor Attachment

Sensor attachment is a common application offshore and subsea as companies attempt to identify patterns and record data. Smart' Band and Smart* Tie have both been extensively utilised in this area.

Pile Protection

Attaching corrosion protective Jackets to Jetty Piles has been one of the most successful applications for the Smart* Band and in terms of strapping has become the number 1 solution in this application. Key benefits are the corrosion resistance, ease of use, competitive pricing and also Smart* Band is not easily recyclable therefore will not get stolen from the Jettys once installed.

Downhole

Downhole is a very specific and aggressive application and attaching cables downhole often can often be a headache. The Smart* Tie is being increasingly utilised in this area replacing standard metal solutions which often causes significant disruption when they fail and fall to the bottom of the well.

Other Applications

The uses for Smart* Band and Smart* Tie offshore and subsea are simply endless.

Wherever something needs to be attached then these products can often be used.