Fittings & Coatings

Fittings and Coatings have various options and applications. View our products below or download our PDF brochure

Fittings

STANDARD DESIGNS, WELDED, BASED

ON DIN/EN/ISO/ASA/ANSI

• Branches

• Weld-in bends

• Crosses

• Reducers, concentric and eccentric, from DN 300 on up

• Segmented bends

• Tees / gusset tees

• Gusset lateral joints (single or two-side gussets)

• Adapter lengths

• Materials: alloy steel or non-alloy steel

SPECIAL DESIGNS TO CUSTOMER SPECIFICATIONS/

DRAWINGS

• From isometric drawings

• From BOM (bill of materials)

• Individual components as well as partially or completely

prefabricated integrated systems

• Distributors, offset transitions, air pots etc.

FITTINGS WITH WELDED RESTRAINED-SOCKET JOINTS

Welded restrained-socket joints in compliance with DIN 2460

up to DN 1600, custom diameters available

• Tees

• Bends / Segmented bends

• Reducers

• Flange adapters

• Valve housings

• Straight unions

• Standard coatings: PE/CM, primer/CM, bare steel/CM, PE/bare steel (see Coatings)

NEW IN 2016

Custom dimensions with wall thicknesses up to 12 mm, with

6 mm socket clearance overall. Example: steel/cast-iron pipe

connection, OD 1054 mm x wall thickness 10.0 mm,

socket OD 1080 mm, ID 1060 mm, wall thickness 10.0 mm,

socket clearance (2x) 3.0 mm

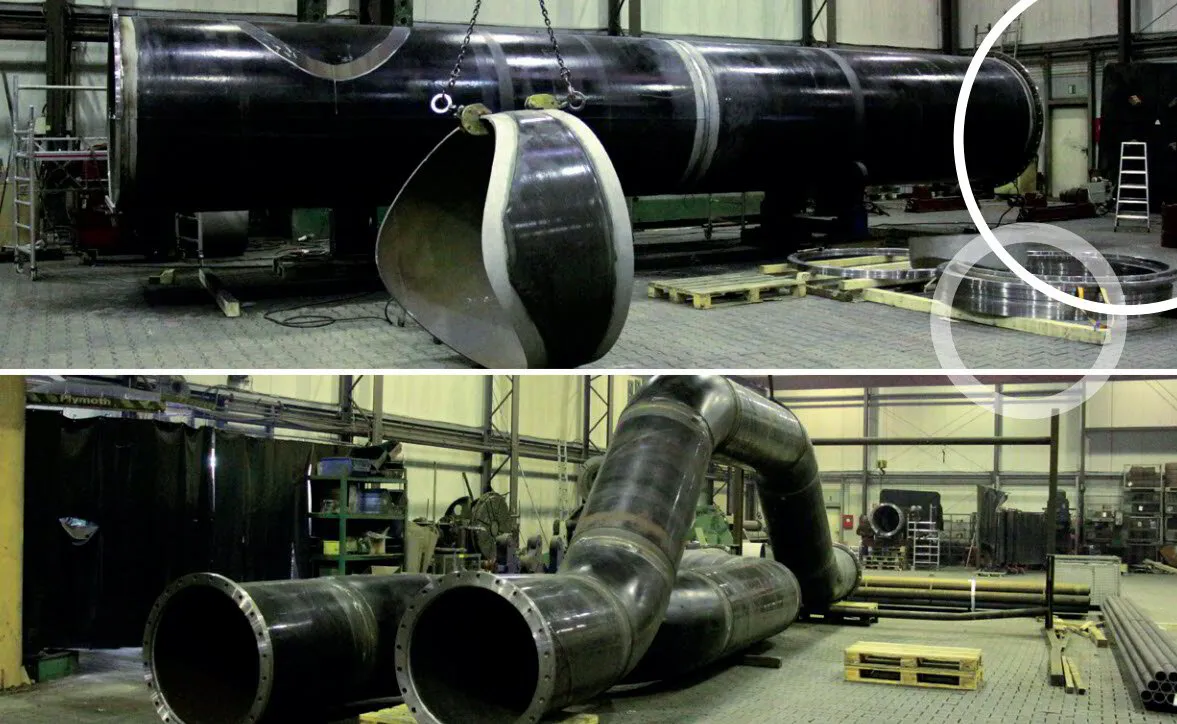

FITTINGS / SPECIAL DESIGNS

We supply standard fittings in compliance with national and international standards as well as special designs to customer specifications.

We offer a virtually unlimited range of products including offsets, culverts, manifolds and many, many others.

All manufacturing processes incorporate continuous monitoring over each fabrication step. Finished products are subjected to 100 %

visual and dimensional inspection and, if required, in-house or thirdparty nondestructive testing.

A test report and a quality certificate compiled by our QA staff are provided for each delivery lot. We use various welding technologies including MAG, MIG, TIG and SAW in semiautomatic or automatic process configurations.

CONNECTIONS

We offer a wide variety of connecting joint technologies for selection in accordance with the fluid conducted, line pressure and installation configuration at hand. The options offered include weld surface preparation techniques, conventional and custom flange connections as well as quick coupling systems.

PE/CM-coated steel pipes for drinking water and wastewater lines – with restrained socket joints permitting quick and easy welding.

Quick coupling systems (rolled groove or cut groove designs) for fire extinguishing or building services.

ZSM – our patented heavy-duty-tensile restrained socket joint for

vertical lines subjected to high line pressure and axial force,

e.g. in shafts.

FITTINGS / SPECIAL DESIGNS

We supply standard fittings in compliance with national and international standards as well as special designs to customer specifications.

We offer a virtually unlimited range of products including offsets, culverts, manifolds and many, many others.

All manufacturing processes incorporate continuous monitoring over each fabrication step. Finished products are subjected to 100 %

visual and dimensional inspection and, if required, in-house or thirdparty nondestructive testing.

A test report and a quality certificate compiled by our QA staff are provided for each delivery lot. We use various welding technologies including MAG, MIG, TIG and SAW in semiautomatic or automatic process configurations.

CONNECTIONS

We offer a wide variety of connecting joint technologies for selection in accordance with the fluid conducted, line pressure and installation configuration at hand. The options offered include weld surface preparation techniques, conventional and custom flange connections as well as quick coupling systems.

PE/CM-coated steel pipes for drinking water and wastewater lines – with restrained socket joints permitting quick and easy welding.

Quick coupling systems (rolled groove or cut groove designs) for fire extinguishing or building services.

ZSM – our patented heavy-duty-tensile restrained socket joint for

vertical lines subjected to high line pressure and axial force,

e.g. in shafts.

NEW IN 2016:

SPRAY-APPLIED PE SHEATHING

Single or multi-layer polyethylene sheathing based on DIN 30670 (or EN 10288) for steel fittings used in underground or offshore applications.

Utilizing state-of the-art flame spraying technology, we securely sheath highly complex component shapes in diameters up to

DN 3000 using an in-house process.

SINTERED PE SHEATHING

Single-layer polyethylene sheathing based on DIN 30670 for steel fittings used in underground or offshore applications. The sintered coat is applied to the grit-blasted component surface in our proprietary powder immersion process.

STANDARD CEMENT

• SAKRET SSM 1 P C35/45 cement, DVGW W347-certified for drinking water applications

• Suitable for use with many wastewaters

This cement mortar is not suited for use in lines carrying wastewaters at pH levels < 6.5. For applications of this type, we offer an alternative

mortar formulated with aluminium constituents.

CM LINING

Cement mortar pipe lining in compliance with DIN EN 10298 (successor of DIN 2614) for steel fittings used in underground or offshore applications. The cement mortar layer is applied in-house using a Type III (manual application) process.

Cement mortar lining of short pipe segments in the diameter range DN 80 to DN 250 is done by a Type II process. We offer all end version types C1 through C5 as specified in the standard.

Coatings

FCM SHEATHING

FCM sheathing based on DVGW specification GW 340 for secure physical protection of outer pipe surfaces as required e.g. at mountainous installation sites.

OTHER SURFACE OPTIONS AND COATINGS

• Blast-derusted to SA 2.5 purity standard in compliance with DIN EN ISO 12944

• Standard galvanisation to DIN EN 1461 / drinking-water grade galvanization to DIN EN 1461 and DIN 10240 A1

• Wet coatings such as:

• 1 or 2-component primer and top coats based on epoxy resins, zinc phosphate, zinc dust, micaceous iron oxide, PUR or other materials; available in various RAL colours

• High-build coatings, e.g. for refrigeration systems,

in conformance with AGI specification Q151

• Thick-film coats with 2-component modified epoxy resin formulations for drinking water and wastewater applications (thickness e.g. 400 μ)

• Powder coats

• And many others!

PE sheathing and CM lining of steel fittings for underground and offshore pipelines carrying drinking water, wastewater, firefighting water, gas and other fluids.

MACHINERY LINE-UP

We fabricate fittings and joints to highest standards using two key resources: our expert staff and our state-of-the-art machinery line-up which includes:

• Fully automatic plasma-arc cutter for component diameters from DN 50 to DN 1500 and lengths up to 12 m

• Portable submerged-arc welders (SAW’s)

• 3-roll bending machines

• Rotating frames for welding of components greater than DN 2000 in diameter

• CNC and conventional lathes

• Roll groover machines

Quality Management

We work in certified accordance with a QM system

which has been in place since 1997. The system was expanded to include our development and design activities in the year 2010.

We are certified as a qualified welding provider.

This certification is verified by periodic inspections confirming compliance with stringent national and international standards. Our certificates, third-party certifications (e.g. from renowned supervisory agency Germanischer Lloyd), welding procedure qualifications and our highly qualified production and QA personnel are your assurance of consistently high quality.

Complete user-customised solutions created from our extensive range of products and options.

Quick delivery times and cost-efficient realisation

(particularly for in-house fabricated items) ensured by:

• Extensive material inventories

• Certified, clearly structured manufacturing processes

• Extensive line-up of modern fabrication machinery

• In-house and third-party nondestructive testing

• Various coating options available in house