SICcast®

SIC Cast various options and applications. View our products below or download our PDF brochure

Click On Image To Expand

SICcast® the Company

Established in the mid-nineties, SICcast® is growing together with our customers.

Started with the casting of several pump parts for the MC series and afterwards for the MCC series of affiliated company DÜCHTING pumps.

The important key feature of the material is the simultaneous resistance against corrosion and abrasion. SICcast® materials are designed for this phenomenon of erosive corrosion. On the basis of the hardness of silicon carbide, 9.7 on the Mohs' scale (hardness close to diamond) and the high filling grade of the components, it has very good results in casting new pump parts and also in coating worn spare parts.

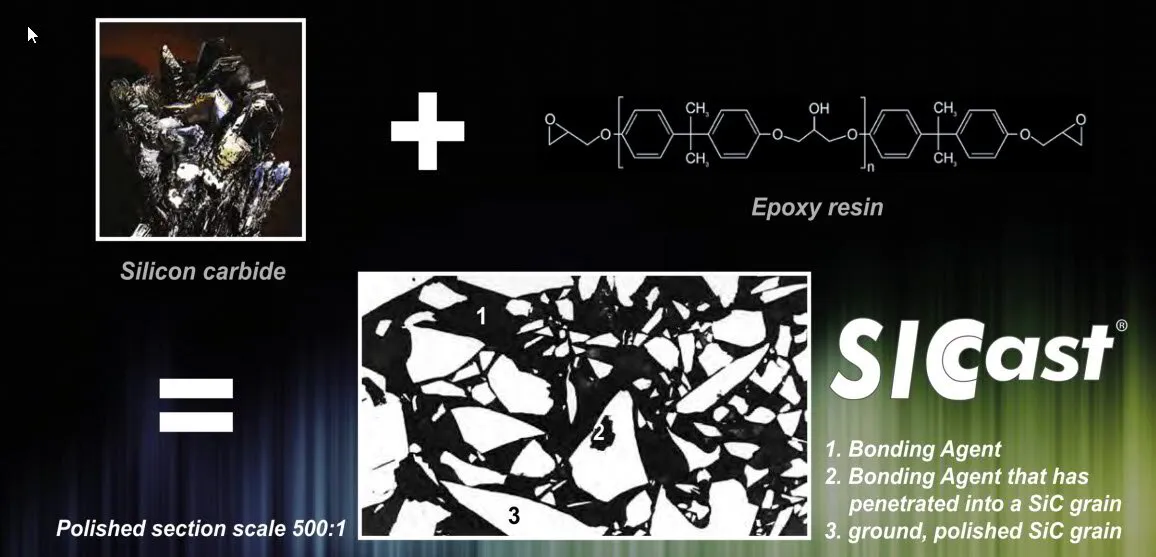

Mineral cast SICcast®

Hard as a Diamond.

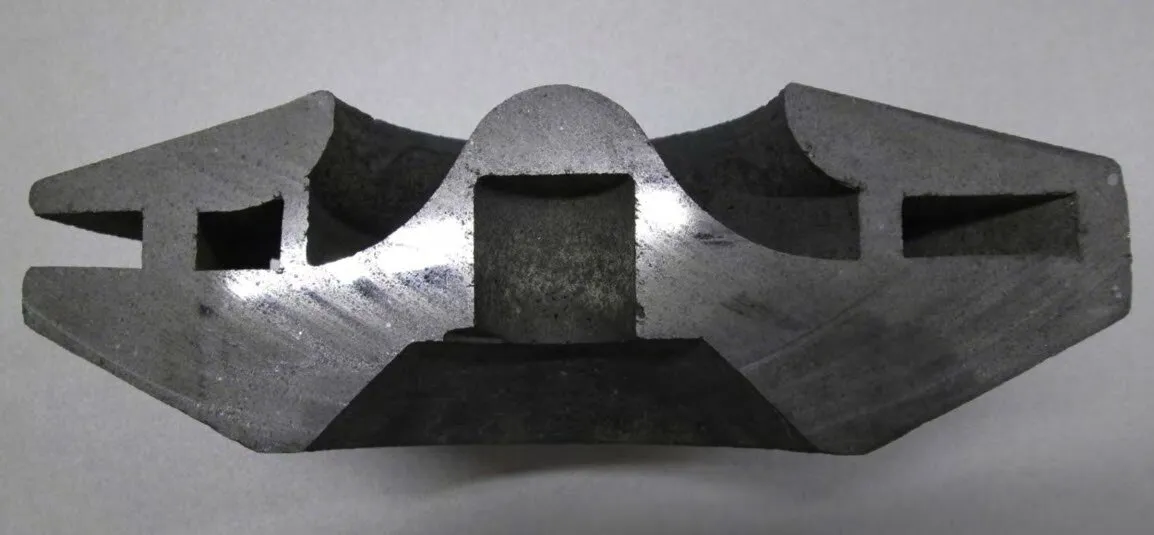

Silicon carbide (SiC) in a special mixture with Epoxy resin cast into precision moulds under vacuum.

Fittings are machined with diamond tools. Thanks to the temperature-controlled casting process, parts of up to 8 tons can be cast.

This material is extremely wear resistant, temperature insensitive and shockproof. It is mainly used in heavy conditions such as in flue gas desulfurization of coal-fired power plants, incineration plants, fertilizer production, titanium dioxide and iron oxide production.

Click On Image To Expand

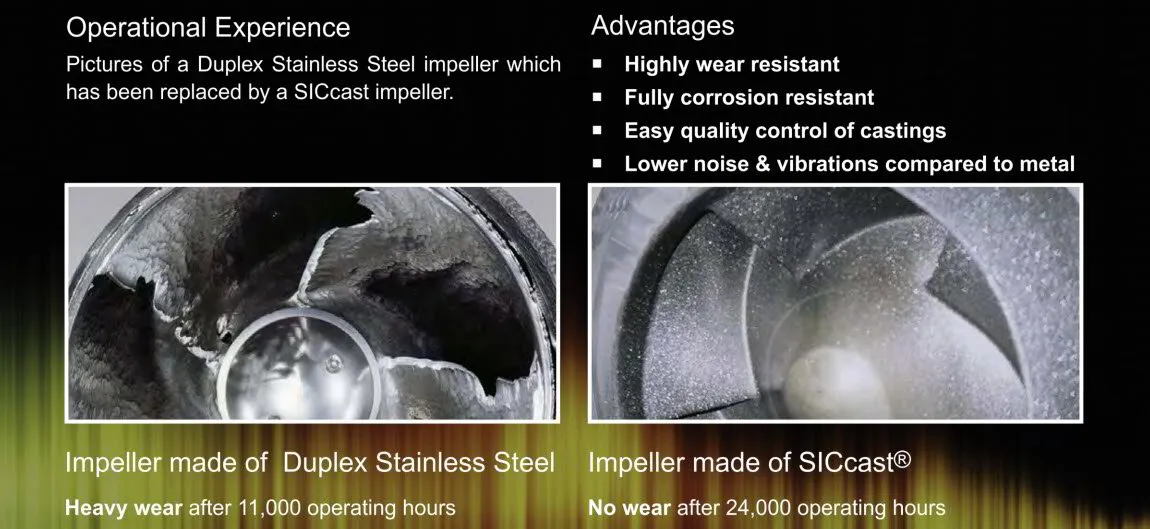

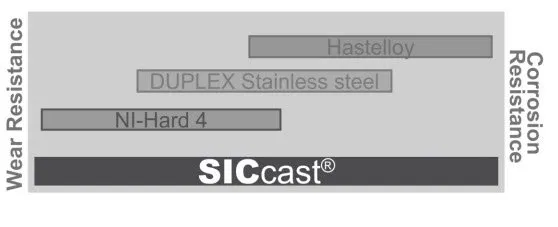

Comparison with Metal

In regards of resistance, metals are only a compromise between conflicting requirements.

Having only corrosion and no abrasion, it will be also possible to use hastelloy. It's the same with abrasion only. Abrasion in a neutral medium can be done by using Ni-hard or similar.

The mineral cast from SICcast® covers both corrosion and abrasion perfectly.

SICcast® materials will be very advantageous if you have solid in combination with a non-neutral medium, a leach or an acid (pH-value 0-12).

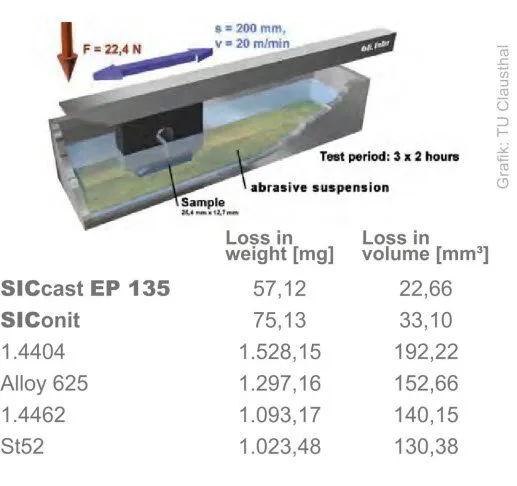

Miller Wear Test

Standard test method for determination of slurry abrasivity.

The Miller Number is an index of the relative abrasivity of slurries. Its primary purpose is to rank the abrasivity of slurries in terms of the wear of a standard reference material. The wear damage on the standard wear block is worse as the Miller Number gets higher.

SICcast® PLUS

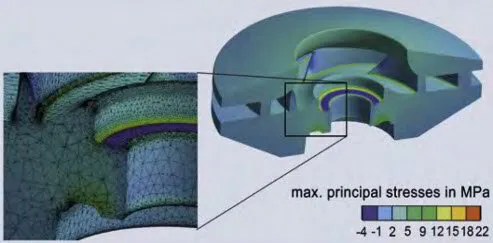

SICcast®PLUS is a silicon carbide ceramic.

Silicon carbide ceramics are used where high wear is expected and can be recommended. where difficult operating conditions - for example, chemical attack or high temperatures - are expected. The innovation in the patented SICcast® PLUS method, is the combination of SICcast® casting with the production process of silicon infiltrated silicon carbide (SiSiC).

So, it is possible to manufacture SiSiC-ceramic components that are subject to shrink by only one percent more than the production chain and therefore not technically difficult to construct than metal castings. In contrast to the conventional production methods can be produced economically from SICcast®PLUS very large and complex components.

Since ceramics have different material properties than steel. for each desired component a feasibility study and a development process are required.

For Repairing SIConit®

A reparing kit with similar characteristics as SICcast®

SIConit® is a silicon carbide coating compound for the repair and protection of metallic surfaces exposed to abrasion, corrosion and acids pH-value 0 - 12.

SIGonit® has a very high silicon carbide content for use in extremely abrasive operational conditions where complex and costly repairs are the norm. The compound can either be used to completely rebuild worn metal surfaces or be used as a preventative coating, often outperforming the original metal in terms of abrasive stability.

SIConit® can be used in place of metal applications, tiling, rubber backing and other coatings.

The entire SICcast® product spectrum

Beside the mineral cast SICcast - EP135,

SICcast® is constantly developing new materials:

• SIConit®

- trowelable wear protection for applications

• SIConit® Kcastable

- wear protection

• SIConit®M trowelable

- wear protection for areas such as pores and joints

• SIConit®F

- brushable wear protection for smooth surfaces and for optimizing the efficiency

• SIOSIC®

- an inorganic high-temperature wear and corrosion resitant material based on silicate technology

• SICcast® PLUS

- silicon carbide ceramic

What can SICcast® do for you?

You have a problem - SICcast® offers the solution.

Beside the products for DÜCHTING PUMPEN. SICcast® is supplying plug and play spare parts for other manufactures.

For example

- - All pump parts

- - Pump adapters

- - Nozzles

- - Hydro cyclones

- - Agitators

For more detailed explanation visit : SICcast.com